AC 220 / 115 V ALTERNATING CURRENT WATER TREATMENT SYSTEMS

The alternating current watermaker is the most used.

It is a very simple and highly reliable system that can produce up to 140 liters of drinking water per hour.

There are 2 options for this system to work, either as a portable without any type of installation or by means of a fixed installation inside the boat but using the minimum possible space.

This watermaker is an excellent option when you want to produce a lot of water quickly and without any complications.

2 COMPONENTS - ONE WATER TREATMENT PLANT

The system is comprised solely of a Pressure Supply Unit (PSU) and a Reverse Osmosis Unit (membranes).

Both parts are necessary to assemble an entire water treatment plant. The feed pump lifts the seawater, filters sediment and puts the system under high pressure, while the reverse osmosis unit draws fresh water from the pressurized seawater flow.

Most of the water is wasted as brine output, while approximately 20% of the volume is withdrawn as drinking water for its reservoirs.

There are several different membrane options for you to select from with your AC system, each to achieve its own specific goal.

ENERGY

With recent advances in generators, batteries, and solar power generation, you have several options for powering your AC system.

Originally designed to run on a minimum of a 2kW Honda generator, it will be easily powered by its built-in generator or a quality 2kVA inverter.

Choose a 230VAC/50Hz or 115VAC/60Hz option to suit the power available in your situation.

FIXED OR PORTABLE INSTALLATION

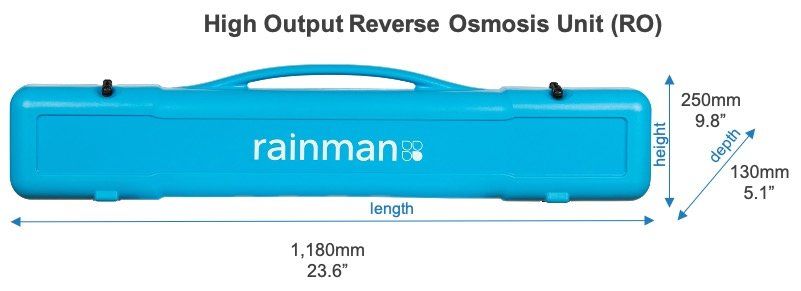

Our system is supplied in a blue casing/case that can be used as a laptop or left attached. If you want to install it, it becomes a 2-item installation only.

Use it totally portable, put it away and every time you want to use it, you'll have it up and running in as little as 2 minutes.

The lid of the membrane housing is opened, and the hoses are removed. Throw them overboard to suck up water, and connect the membranes to the pressure equipment through 1 single pipe with quick connect. That's it, connect the power supply and you can now generate drinking water.

Another option would be to make a fixed installation using the grommet and connect the pipes to the grommet taps.

DIFFERENT MEMBRANE OPTIONS

You have three basic membrane options depending on your water requirements, available space, and budget.

All three membrane options are compatibles with the Mains power supply and are available in cased and caseless configurations.

BASIC CHARACTERISTICS OF MEMBRANES

| HIGH CAPACITY |

|---|

| 100 - 140 LITERS/HOUR |

| 2 MEMBRANES OF 40" (1.016m) |

| MAXIMUM PRODUCTION CAPACITY |

| NEED FOR SPACE |

| COMPACT |

|---|

| 50 - 70 LITERS/HOUR |

| 2 MEMBRANES OF 21" (0.53m) |

| MEDIUM CAPACITY |

| LITTLE SPACE NEEDED |

| ECONOMIC |

|---|

| 50 - 70 LITERS/HOUR |

| 1 MEMBRANE OF 40" (1.016m) |

| MEDIUM CAPACITY |

| THE MOST ECONOMIC |

HOUSING OR NO HOUSING

The system can be purchased in the version with a blue casing or in the version without a casing. Price, performance, and power consumption are identical between the two options, so your specific requirements will decide which is best suited for each application. The following table summarizes the differences between the two options.

DIFFERENT MEMBRANE OPTIONS

You have three basic membrane options depending on your water requirements, available space, and budget.

All three membrane options are comThey are compatible with AC power supply and are available in cased and non-cased configurations.

| COMMON FEATURES (WITH HOUSING AND WITHOUT HOUSING) |

|---|

| Fully sealed 1.5HP induction motor |

| Stable power consumption of 1250 watts |

| Current draw 6 amps (230 VAC) or 12 amps (115 VAC) |

| Power cord length: 3 meters (10 feet) |

| Plug Type Options: European |

| Suction pump uses standard impeller |

| Maximum elevation of 2 meters (6 feet) above sea level |

| Main pump: WMR 316 stainless steel high pressure triplex plunger pump |

| Relief valve built into 316SS/ceramic main pump to prevent over-pressurization |

| Sound levels: 62 dB at 6 meters (20 feet), see table |

| HOUSING VERSION |

|---|

| Pressure unit housing: glass fiber reinforced nylon with strap |

| Membrane shell: roto-molded polyethylene |

| Pipe installation kit sold separately |

| Single 10″ x 2.5″ 5 micron standard pre-filter to remove sediment mounted on pressure unit |

| Produced water flow meter from 0 to 150 lph (40 gph), integrated into the membrane housing |

| Control assembly: valve/manometer integrated in the membrane box |

| 5 meter (16 foot) inlet hose equipped with one-way valve to stay primed, with removable strainer |

| 3 meter (10 foot) saltwater discharge hose |

| Pressure unit weight 24 Kg |

| VERSION SIN CARCASA (NAKED) |

|---|

| Easy pressure unit mounting kit: fiberglass reinforced nylon for high rigidity and tensile strength |

| Easy Membrane Mounting Kit: Glass-reinforced nylon for high rigidity and tensile strength |

| Pipe installation kit included with the kit |

| Single 10″ x 2.5″ standard 5 micron pre-filter to remove sediment with SS316 mounting bracket |

| Produced Water Flow Meter 0 to 150 lph (40 gph), with SS316 Mounting Bracket |

| Valve control/pressure gauge assembly on the end of a 5 meter (16 foot) high pressure hose for remote mounting |

| 5 meter (16 foot) inlet hose |

| 20-foot (6-meter) saltwater discharge hose |

| Pressure unit weight: 23 kg (51 lb) |

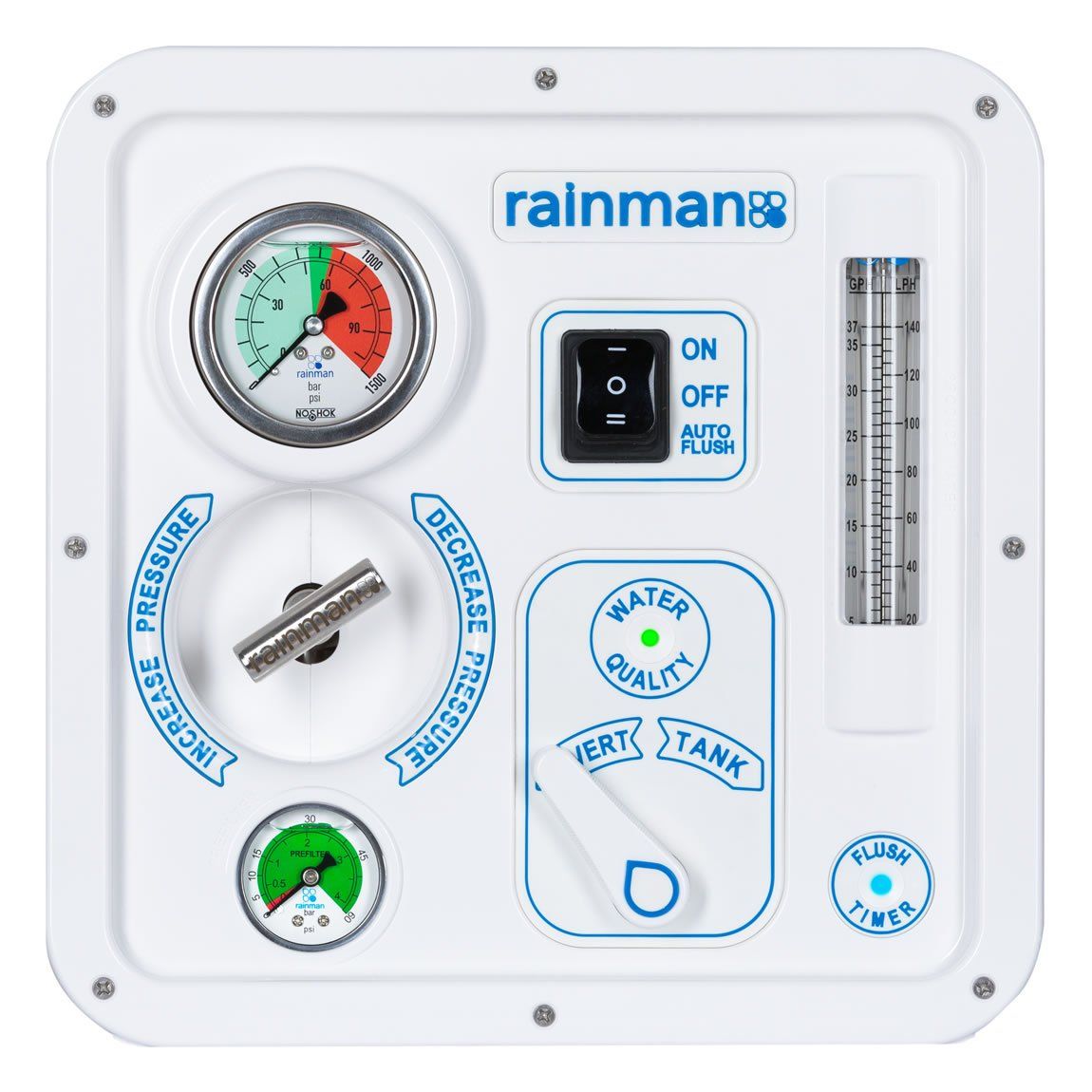

CONTROL PANEL

The optional control panel provides remote management capability for your installed Rainman watermaker.

It is a very functional additional component that will improve the management and control of the water treatment plant.

It is an ASA injection molded acrylic panel that stays true to the Rainman image of elegant simplicity and easy handling.

AUTOMATIC WASH

Your Rainman watermaker is a very sturdy piece of equipment, but taking care of a few things will prolong its life.

· Regularly flushing your Rainman with fresh water will maximize the life of your watermaker's membranes.

· The optional automatic flushing system incorporates a solid-state programmable timer that will flush your Rainman watermaker after each use and every seven days thereafter.

·Incorporates protection in case your boat loses power during or between cleaning cycles.