RAINMAN PORTABLE POTABILIZER

Why laptop?

Originally, Rainman designed the watermaker as portable, in order to solve a need in the market, in fact it has many advantages over other types of installations.

·It is not necessary to install the equipment. In 5 minutes you can have the equipment working.

· If you are a yachtsman or cruiser, you can easily remove around 2/3 of a crew member's weight by taking the watermaker out on shore, for example for a regatta.

· There are no additional holes in his helmet.

· If you have space limitations, you can remove the system for more people and equipment on shorter trips.

· If maintenance is required, take the system to a technician instead of having a technician come to your boat.

When you change ships, you can take your gear with you without dismounting.

· You can lend it to a friend.

· Reduced initial cost due to no costly installation process.

· You can fill your neighbors' tanks with our production water extension hose.

· You can easily resell the system if it is no longer used.

Types of systems available

Any of our three pressure units can be used as a portable:

Alternating current watermaker

The main characteristic is that it must start and work with a portable generator, for example: Honda with a minimum of 2 kVA.

This unit has become the most popular system in our range. It can also work with a good quality 2kVA inverter.

Gasoline watermaker (gasoline)

Two components, one watermaker

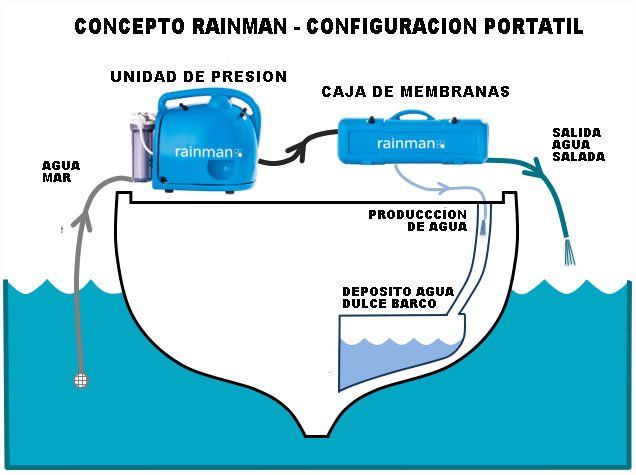

The system is comprised of a Pressure Supply Unit (PSU) and a Reverse Osmosis (Membrane) unit. Both parts are necessary for a water treatment plant to work. The pressure unit draws in seawater, filters out sediment and puts the system under high pressure, while the reverse osmosis unit draws fresh water from the pressurized seawater stream. Most of the water is wasted as saltwater waste output, while approximately 20% of the volume is withdrawn as drinking water for its reservoirs. There are a number of membrane options for you to select with your portable system, each to achieve its own goal.

Flexibility for the future

If you are not sure if you want to have a portable or stationary watermaker, the best option is to buy the portable version. Later and with little investment, when you have already tested its operation, you can make it fixed. It also gives you more time to determine where you want to install the system, find the best location.

Use of the water treatment plant

After a few uses, it will only take about two minutes to assemble and disassemble your watermaker.

More details are available in the operations manual, but the steps are:

· Connect the black high pressure hose from the membrane box to the quick connect coupling on the pressure supply unit (PSU).

· Put the intake hose in sea water.

· Place the green waste outlet hose overboard.

· Power on the system.

· Slowly pressurize the system to 55 bar (800 psi) using the control valve. Fresh water will start coming out of the white production hose.

· Let it run for a couple of minutes, then place the production hose in the filler neck of the ship's tank.

· When the tank is full, depressurize the system and store it again.